Electronics contract Manufacturing Services

Argus Systems (AESPL) is one of India’s leading electronics manufacturing companies, specializing in quick-turn prototypes and low to medium-volume production, aligned with global quality management standards including IATF 16949 for automotive, ISO 13485 for medical devices, and AS9100D for aerospace and defense (Scope: Manufacturer of Printed Circuit Board Assemblies, Electromechanical Assemblies, Cable Assemblies, and Box Builds).

Our Electronics Manufacturing Services (EMS) division offers comprehensive solutions including PCB fabrication, component sourcing, and full turnkey PCB assembly. Our state-of-the-art manufacturing facility is supported by a highly skilled team dedicated to cost-effective procurement of quality components and precision PCB assembly, tailored to meet the needs of high-tech OEMs and product companies. We provive Consistent quality with Around 99.5% yield, backed by FAI, MES system and 3D AOI.

As a complete electronic product development organization , Argus brings deep expertise in Design for Manufacturing (DFM), Design for Testing (DFT), and Design for Assembly (DFA). These principles are systematically applied to every project to minimize errors, reduce rework, and accelerate time-to-market.

Our facility offers end-to-end turnkey manufacturing services—from prototyping and pre-production to volume manufacturing, post-sales repair, supply chain management, and component sourcing. We specialize in delivering cost-effective, high-mix, and complex electronic manufacturing solutions for a global clientele of technology-driven OEMs.

Turnkey PCB Assembly

Argus Systems is one of the Leading PCB Assembly Services company with specialization in quick turn Prototypes and low to medium scale Electronic manufacturing with the Highest Quality and on-time delivery.

Rigid-Flex , HDI PCB Fabrication

Argus Systems is a leading manufacturer of professional high quality multi-layered Rigid, Flexible, Flexi Rigid, Metal Core, and PTFE Teflon Printed Circuit Boards (PCB) for Defence, Medical, Industrial, IoT, Automotive.

Manufacturing Supply Chain

Argus is a leading electronic components supplier addressing all types of applications and supplying to Electronics contract manufacturing industries, Public Sector Companies, R&D, and educational Institutions.

Turnkey Box Build Assembly

Our capabilities include Mechanical housing design and fabrication, cable assembly, sub-system, and full system integration.We leverage our vertical design & manufacturing model, capabilities under one roof in a cost-effective manner

Turnkey Wiring Harness Assembly

Argus has the design capability and practical experience to build wire harness and cable assemblies that require any number of connectors, styles of termination, or types of cable.Increasing your application’s performance and productivity.

Regulatory Compliance Testing

Our Regulatory Compliance Services ensure that products & solutions comply with the many global requirements for safety, electromagnetic compatibility, and environmental requirements for Electronic Systems.

Turnkey PCB Assembly

- Turnkey PCB Assemblies with the Highest Quality and on-time delivery.

- Quick turnaround time For NPI & Low Volume manufacturing.

- Comprehensive & multi-stage QC process for consistent quality and high production yield.

- Emphasis on material verification to minimize in-process delays rejects & reworks.

- Development of Customer specific Test Jigs for testing.

- Cost-effective, high mix, low to medium volume manufacturing solutions

Wire Harness & Cable Assembly

- Custom Wire Harness Assemblies.

- Semi-Rigid and Semi-flexible Cables.

- Chassis Wiring and Assembly.

- EMI Shielded Cable Harness.

- Mil-Spec Connectors, D-38999 Circular Connectors.

- RF Broadband Cable assembly and wire harness

- Automotive wiring harness, Industrial wiring harness.

- Airborne/Military Wire Looms and Cable Looms

- Medical Wiring Harness assembly.

PCB Manufacturing

- High-Reliability Multi-layer PCB.

- Double sided, multi-layer Flexible PCB and Rigid flex PCB.

- PCB Manufacturer for RF & Microwave Applications.

- High frequency and High bandwidth RF PCB Fabrication.

- RF PCB with Mixed dielectrics (hybrids).

- HDI PCB with Up to 12L "any-layer" Structure.

- PCB manufacturing with Embedded passives.

- Buried metal core constructions.

- Heavy copper PCB up to 10 oz.

- IC Substrates & Substrate like PCB.

SMT Stencil & soldering Pallet

- Laser Cut PCB Stencil for PCB Assembly applications.

- frameless and Framed SMT Micro stencil, SMT mini stencils and full board SMT stencils for solder paste applications as per IPC-7525B standard.

- framed Full board SMT Stencil for top & bottom side.

- PCB stencil frame material : Aluminium.

- SMT stencil foil material : stainless steel.

- PCB stencil foil thickness : 4/5/6/8 mil.

- stepped SMT stencils solution for optimized solder paste release and improved volumetric repeatability for complex component mixes.

Mechanical Fabrication

- Aluminium Die Casting parts.

- Aluminum sheet metal fabrication.

- Injection Molded precision plastic parts.

- Sheet Metal Enclosures.

- Flame Proof, ATEX , IECEX approved.

- IP5x & IP6x Plastic enclosure.

- Custom sheet metal mechanical fabrication solutions in aluminium, mild steel and stainless steel with sheet thickness 0.5 mm to 10 mm.

- Rapid prototyped SLA & SLS plastic parts and enclosures with materials like ABS, PP and PLA.

Box build assembly

- Experienced and Skilled Top Level Assembly team.

- Assembly lines equipped with PCs, Scanners, Printers , laser Marking Machines.

- Equipped with IP Cameras to monitor production process remotely by customer.

- Vast experience in for sub-system, System and rack Level box build assembly enclosures in Plastics, Aluminum, mild steel and stainless steel.

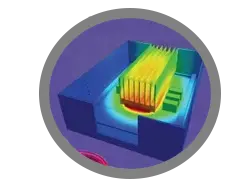

- Box build assembly Considers heat dissipation requirements, Product IP ratings, Design for manufacturability & Assembly and cost factors.

Test Jig, Test fixture, EOL Testing

- Customer specific Test Jig & Test fixture fabrication to test Bare PCB and PCB assemblies for end of line testing ( EOL testing).

- Design and manufacturing of dual access, bi-level PCB Test fixtures.

- Test jig to support individual PCBA as well Panel.

- Support for DFT implementation and Probe accessibility audits during product design stage.

- Test program development for Automatic Test Equipment.

- Flying probe testing for PCB Assemblies.

- Test automation framework : LabVIEW, MATLAB

Conformal Coating

- We have the knowledge and necessary process and resources to address requirements pertaining to PCBA coatings with material such as polyurethane, silicon, acrylics, water-based coatings and non-VOC based coatings.

- Conformal coating services with dipping, spraying, brushing and selective robotic coating.

- Conformal coating Material such Humiseal 1B31, 1B73, 1A33, 3M Novec, ACC silicones ACC15, Trinity shields PC101-18 Peters Coating, HYSOL PC20M, ELANTAS CE1170, HPA, Surclean PCC1704

Epoxy Potting & encapsulation

- In the Electronic potting and encapsulation process, an electronic assembly is placed inside a mold which is then filled with an insulating liquid compound that hardens permanently protecting the assembly the mold is part of the finished article and can provide shielding or he

- Electronic products with Potting compound such as Hard Tamper Proof Potting Compound, Silicone Potting Encapsulant, flexible clear transparent epoxy potting compound.

Supply Chain Management

- Alliance with Tier-1 manufacturers for global procurement & sourcing.

- Buying and planning linked to corporate commodity management.

- Extensive experience with imports, customs duties, and tariffs.

- sourcing spans across mechanical, electrical, electronic components and sub-assemblies.

Compliance management

- Product Safety compliance Testing and certification.

- Environmental Compliance Test Plans and Procedures Development.

- Electromagnetic Compatibility Tests.

- Compliance Declarations (RoHS, REACH, Conflict Minerals).

- Validation as per Compliance template of UL, FCC, CISPR, IEC

- Validation as per Compliance template of MIL STD 810E, MIL STD 461F, JSS 55555.

First Article Inspection, PPAP

- As a leading inspection provider, we offer you unrivaled experience and expertise in providing first article inspection for PCB Assemblies, Wire harness Assembly and Box Build Assembly.

- With our global reach, we provide first article inspectors with our experienced team for customer and OEM requirements.

- Planning and scheduling of the first article inspection in close communication with the product supplier, OEM and customer.

- Performing the first article inspection.

- Reporting.

- The Production Part Approval Process (PPAP) quality control process implementation.

- PPAP documenation.

Electronics packaging

- Electronics packaging design and manufacturing

- we follow electronics packaging best practices to provide defect free parts, maximize production efficiency and ensure safety while minimizing overall packaging and transportation costs to meet each customer plants logistics and operational requirements

- Corrugated Box

- Luxury Product Packaging

- Jumbo Shipment Box

- we adher to Packaging standards for Electronic Components and wire harness.

- we follow Packaging standards for Plastic and metal parts.

- Palletizing : Palletizing rules when returnable Palletizing rules when expendable.

Electronic Product Life cycle Management

- Forecasting – predicting obsolescence risk or dates(frequency of obsolescence). We Use long-term forecasting while continuously monitoring the supply chain for precursors. Abandon the long-term forecast when precursors appear.

- Mitigation – minimizing the impact of the problem after it occurs using a set of reactive firefighting approaches.

- Planning - planning design refreshes based on forecasted obsolescence dates and technology insertion roadmaps in order to minimize part life cycle Management costs.

- Parts Chasing-Accurately provide the current status of item.

Keypad Solutions

- Design and manufacturing of Multiple types such as membrane keypads, silicone rubber keypad, flexible membrane keypad and capacitive keypads for a wide range of industries and applications.

- Argus Engineering and Hardware Design assistance ensures that your keypads meets all of your specifications for prototype and production quantities.

- Flexible Membrane Keypad Construction with tactile/ Non-tactile

- Rigid PCB Keypad Construction with tactile/ Non-tactile

- EMI/RFI Shield: Aluminium Foil/Metal Mesh/ITO

- EMI Shielding for Display Window

- ESD compliance keypad option

- Graphic keypad overlays

Electronics Manufacturing Quality standards

- PCB Assemblies conforms to IPC-A-610 Class-III STD or as per customer Requirement.

- MSD components are pre-baked in accordance with the IPC/JEDEC-J-STD-033 , prior to the PCB assembly.

- PCB Pre-baking & Pre-assembly QC is done in accordance with IPC-1601A. Soldering is done in accordance with IPC-7530A STD.

- Assembly, Re-work & QC are done in accordance with the IPC-A-610-II/III and IPC- 7711/21 STD.

- PCBA’s are cleaned, considering the complexity & presence of sensitive components accordance to IPC-CH-65 and is conforms to IPC J-STD-001E.

- PCBA conformal coating & potting are performed according to the IPC-CC-830 & J- STD-001.

- Cable and Wire Harness Manufacturing as per IPC/WHMA-A-620 standard.

- ATEX, IEC Ex compliant electronic system assembly.

- MIL-PRF-55110 Type 2 & Type-3 for GY, GF, GI, GM, BI.

- MIl-P50884 Type-4 for Rigid-flex PCB.

- IPC-2222: Rigid organic circuit boards material selection, mechanical properties, and hole size.

- IPC-A-600: Printed-board acceptability.

- IPC-4101C: Base material selection.

- IPC-6011, 6012, 6013, 6017, and 6018: printed-board quality and reliability.

Reach Argus Application Engineering team to discuss Requirement for contract Electronics Manufacturing Services.

Argus Systems (AESPL) is a globally recognized contract Electronics Manufacturing company (EMS) supporting PCB Fabrication, Turnkey PCB Assembly, Cable Assembly, Wire Harness Assembly, switch & Keypad manufacturing , Conformal Coating services , Expoxy Potting & encapsulation services, PCBA Stencil fabrication, Mechanical fabrication, Turnkey Box Build Assembly, Test fixture, System Assembly, Regulatory compliance Testing, EOL Testing, Electronics manufacturing supply chain solutions for Its Global OEM & ODM Clients in India, USA, UK, Germany, France, UAE, Saudi Arabia, and Australia