PCB Conformal Coating services , Electronic epoxy Potting & encapsulation services

Argus Systems (AESPL) is one of the leading electronic manufacturing company with specialization in quick turnaround of Prototypes and low to medium scale production.

PCB Conformal Coating is a protective chemical coating that conforms to the circuit board topology. The conformal coating helps in protecting electronic circuits from harsh environments that may contain moisture and chemical contaminants.

Electronic potting and encapsulation is a process of filling a complete electronic assembly with a solid or gelatinous compound for resistance to shock and vibration and for the exclusion of moisture and corrosive agents.

PCB Conformal Coating Services

- Dipping- This is limited to materials that do not cure quickly by moisture, oxidation, or light.

- Selective Robotic Coating- If the Correct dispense head is selected all coating types like Asymtek, PVA, or DIMA will be applied.

- Spraying- All conformal coating can be applied by using hand spray or

- Brushing- In brush coating requires extremely proficient and skilled operators in order to be suitable for production.

Advantages of conformal coatings:

- Protect the assembly against chemical and corrosive

- Minimize environmental stress on a PCB Assembly.

- Insulating properties allow a reduction in PCB conductor spacing.

- Helps in eliminating the need for complex, sophisticated enclosures.

- Lightweight

- Protection against thermal and mechanical shock

- Protest against environmental hazards including moisture chemicals and other corrosive elements

- Easy removal, repair, and replacement

- High flexibility

Conformal coating material supported:

- Humiseal 1B31, 1B73, 1A33

- 3M Novec

- ACC silicones ACC15

- Trinity shields PC101-18

- Peters Coating

- HYSOL PC20M

- ELANTAS CE1170

- HPA

- Surclean PCC1704

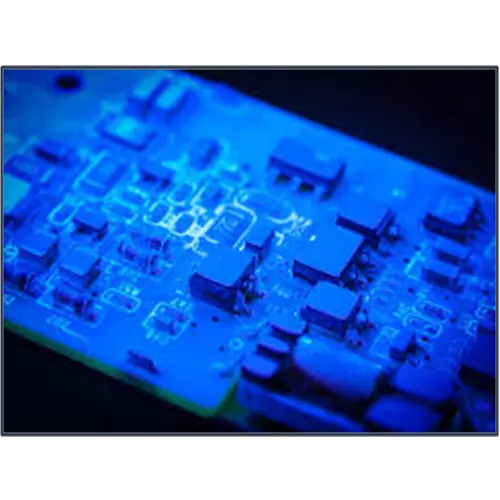

Conformal Coating Curing Services:

- PCB conformal coatings cure through various methods, including heat curing (using an oven to speed up polymerization), UV curing (using ultraviolet light for rapid solidification), and moisture curing (where the coating reacts with ambient humidity to form the polymer).

- UV conformal coating curing services involve using ultraviolet light to solidify a liquid coating on a circuit board, providing protection from moisture, chemicals, and vibration.

- The best curing method depends on the coating type and production volume, with some systems requiring a two-step cure combining mechanisms like heat with UV curing for complete hardening, especially in shadowy areas beneath components.

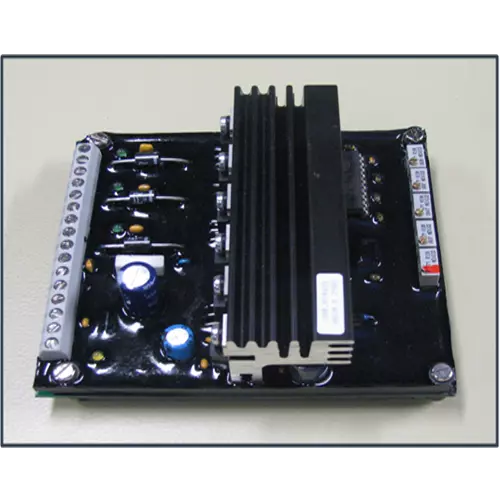

Electronic Potting And Encapsulation

- Electronic potting is a process of filling a complete electronic assembly with a solid or gelatinous compound for resistance to shock and vibration and for the exclusion of moisture and corrosive agents.

- In the Electronic epoxy potting and encapsulation process, an electronic assembly is placed inside a mold which is then filled with an insulating liquid compound that hardens permanently protecting the assembly.The mold is part of the finished article and can provide shielding or heat-dissipating functions in addition to acting as a mold.

- Electronic Potting compound support: Hard Tamper Proof Potting Compound, Silicone Potting Encapsulant, flexible clear transparent epoxy potting compound.