Hardware Reverse Engineering, Software reverse engineering

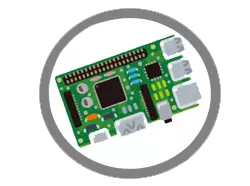

Product Reverse engineering is the process of analysing an existing product or design for the desire & purpose of replicating a similar functionality or the behaviour without the aid of original manufacturing or actual design documents. Product Reverse engineering ( hardware reverse engineering, software reverse engineering ) is a wide term and is applicable in multiple fields including electronic engineering, software engineering and mechanical engineering.

Hardware and software reverse engineering is a challenging task as the information given is limited and the task requires committed experienced professionals to start from minimal information to the point where the production of the new design can take place.In electronic engineering there is no standard to govern hardware reverse engineering, Printed Circuit Board Reverse engineering however from a software reverse engineering perspective IEEE has defined reverse engineering as “The process of analysing a subject system to identify the system’s components and their interrelationships and to create representations of the system in another form or at a higher level of abstraction”.

PCB reverse engineering is a grueling process that seems impossible sometimes but the right experience, dedication and success gives paramount satisfaction and overshadows the hurdles faced in the journey. If the product or the PCB is re-engineered by us, we take responsibility for the custom developed hardware to test the functionality as per the original product. This assurance can not be given by most of the design bureau as either they are in to only manufacturing or only in the electronic product design.Our services are widely appreciated by clients for their quality, timely execution and genuine prices.

Hardware and Software Reverse engineering , Re-Engineering Case studies

Power & Energy

Power & Energy

- Re-Engineer Product (Hardware & Software) with New Feature addition.

- Product Certification and Manufacturing of Mid-volume quantities for field deployment.

Process & Manufacturing Industry

Process & Manufacturing Industry

- Reverse Engineer Products & Manufacture spare cards to be used in steel and superalloy manufacturing Plant.

- Re-Engineer Product (Hardware & Software) with New Feature addition for application of Water Purification & Vending Machine

Railways

Railways

- Reverse Engineer Products & Manufacture spare systems to be used in railways having application of minimum voltage relay, Power Control Card, Minimum Voltage Indicator

Telecom

Telecom

- Reverse Engineer PCB Assembly to generate schematic and Bill of material for Debug/RMA activities of satellite modem.

Industrial

Industrial

- Reverse Engineer Product & Manufacture low to mid-volume quantities having application of Audio amplifier, power supply, Tilt Detector, RF Amplifier

Technology Migration

Technology Migration

- Reverse Engineer Product, from Through hole parts to SMD parts and Manufacture mid-volume quantities.

- Reverse Engineer Ceramic PCB to FR4 PCB & Manufacture low to mid-volume quantities.

Reasons for Reverse Engineering

- Obsolete products with no circuit diagrams or documentation available.

- Re-positioning of obsolete components.

- Design recovery.

- Products Re-designed for RoHS/ WEEE compliance.

- While retaining the core features & logic of existing systems migration to emerging technologies.

- Design Changes For Increased performance.

- For new Feature additions.

- Manufacturing process changes: Through-hole to SMD parts Migration

- To address support/Repair issues on older PCBA where documentation does not exist.

- Cost Optimization /Lower System Cost

- Reduced life-cycle costs

- Competitor Analysis and gain

- To improve operations, maintenance and support issues on the older circuit Boards.

PCB Reverse Engineering Tools

- Continuity Tester, Milli-Ohm meter.

- Inductive short tracer.

- Stereo Zoom Microscope,PCB Optical inspection.

- Sandpaper – Solder Mask Removal.

- Fiberglass Scratch Brush – Solder Mask Removal.

- Abrasive sand Blaster – Solder Mask Removal.

- Stripping chemicals such as Ristoff C-8, and MagnaStrip 500 for chemical based Solder mask Removal.

- Chemical-resistant drop cloth, hot plate, beaker, thermometer, glass tray, and stainless steel tongs for chemical-based Solder mask Removal process.

- UV Laser System - Solder Mask Removal.

- Delayering: Sandpaper – PCB Delayering.

- Dremel tool – PCB Delayering.

- CNC milling machine – PCB Delayering.

- Surface grinding machine – PCB Delayering .

- X-ray (2D).

- Computerized Tomography (3D X- ray).

Steps of PCB Hardware Reverse Engineering

- Assign reference designations to unmarked components before starting PCB reverse engineering.

- Create a Component level BOM.

- Design -Identify the system’s components and their interrelationships.

- Components Placement & Mechanical.

- XY locations of Connectors, LED, Switches etc.

- Board mechanical Mounting holes & any special cuts on Boards, Board size etc.

- Download datasheets, application notes, and architecture information.

- Create a netlist.

- Make the Schematic Drawing and PCB Layout.

Electronic Product Teardown analysis

Hardware Teardown analysis

- IGBT Module Bill of Material and Cost Analysis used in Drive Control application.

- Teardown Analysis of potted PCBA (TPMS) to understand the Bill of material for competitor Product e-BOM Cost Analysis.

- Teardown Analysis of potted PCBA (Automotive ECU) to understand Design Architecture and Bill of material having application of TPMS.

Silicon Die Analysis

- Analyse Integrated Circuit Die for process and Cost Analysis

Where Argus Can help for Electronics Hardware Reverse Engineering

Argus PCB Re-Engineering Services are designed and developed in accordance with the specific customer’s needs and demands.

- Obsolete products with no circuit diagrams.

- Products Re-designed for RoHS/ WEEE compliance.

- Through-hole to SMD parts Migration.

- Migration to emerging technologies while retaining the core features/logic of existing systems

- To improve operations, maintenance and support issues on the older circuit Board.

- For increased performance.

- Reduced life-cycle costs and lower System Cost.

Product Re-Engineering Quality & Delivery Process

- Dedicated Resources with program management.

- Phase gate-controlled project management.

- Support of Deliverables Post acceptance.

- Automated Processes and control.

- Documentation and reporting system with Live reporting of data.

- Project lead and account Manager are directly involved in assuring the success of the program.

- Commitment to KPI.

- Commitment to Quality of product and Service Delivery.

- Transparent and competitive business Process.

- A Collaborative business approach leads to Business risk reduction.

Argus Systems (AESPL) is a globally recognized Product Engineering and Electronic contract Manufacturing company providing electronic product design, product Reverse Engineering, Product Re-engineering, Hardware reverse engineering, Software reverse Engineering, Printed Circuit Board Reverse Engineering, electronic product teardown analysis, value engineering, Product Life-cycle Management services.

Electronics Manufacturing Includes PCB Fabrication, PCB Assembly, wire Harness & cable Assemblies, Conformal Coating, Electronic Potting, PCBA Stencil fabrication, Box Build assembly, Test fixture, System-Level Assembly, Regulatory compliance Testing and Electronic manufacturing supply chain solutions for Its Global Clients in India, USA, UK, Germany, France, and Australia.